rockwell hardness tester mechanism|rockwell hardness calculation formula : solutions The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. webKinnechan's profile page. EroMe is the best place to share your erotic pics and porn videos. Every day, thousands of people use EroMe to enjoy free photos and videos. Come share your amateur horny.

{plog:ftitle_list}

Resultado da 29 de jan. de 2021 · A página é bastante intuitiva e fornece algumas opções aos interessados. Para mandar o seu currículo, prossiga com o seguinte passo a passo: Passo 1- Acesse o site da Havan; Passo 2- Vá até o rodapé do site e clique em “Trabalhe Conosco;”. Passo 3- A página vai abrir com .

Articles - Rockwell Hardness Tester 101: Everything You Need to Know. Table of Contents. What is the Rockwell Hardness Test? Rockwell Hardness Test Procedure: A Step-by-Step Guide. How Does the Rockwell Hardness Test . Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.The hardness tester consists of fuselage, force exerting mechanism, measuring instructions and specimen support institutions and other components (see figure 1)。 Fuselage for a closed . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation.

Rockwell Hardness Testing Machine HR-530 Series Unique electronic control makes the HR-530 series of hardness testers capable of Rockwell, Rockwell Superficial, Rockwell testing of plastics . Table up/down mechanism Manual (automatic braking and load sequencing) Control unit Color touch-panelA Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .

Rockwell hardness test is the rapidest, easiest and most economic testing method in mechanical performance tests. Featuring high efficiency and easy-to-operate, the hardness values can be obtained directly. In most cases, it can fulfill the work that other . mechanism (2, 20), measurement mechanism (23), load changeover mechanism (24),The 574 Series Wilson Rockwell Hardness Testers offer quality, durability, and an industry leading Gauge Repeatability and Reproducibility (GR&R) making this hardness testing machine best in class. This system is available in Regular or Twin Scale models and capable of testing in all of the regular and superficial Rockwell hardness scales and .

rockwell hardness tester diagram

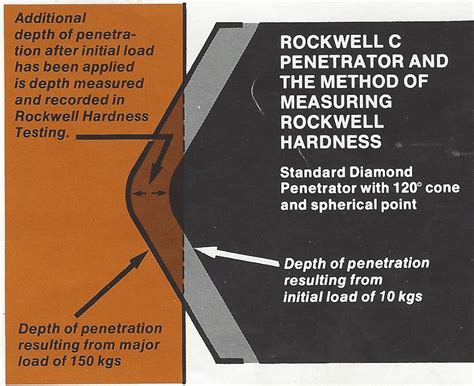

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .The ZwickRoell Indentec Rockwell hardness testers with dead weights and frictionless load application. Available in different configurations for both classic Rockwell and superficial Rockwell hardness testing. The innovative nose mounting feature of the indenter provides unsurpassed accessibility for hard to reach measuring points. Inner surfaces of parts can be .profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds,

The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .

Rockwell hardness test is to apply diamond cone indenter or steel ball indenter to the specimen surface in two steps as shown in Fig-1, which shall be retained for a certain period of time, and measure the residual . 5 Descriptions of Mechanism Parts The tester is composed of machine body (1), indenter (20), loading and unloading mechanism (2),1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .Other articles where Rockwell hardness tester is discussed: hardness tester: The Rockwell hardness tester utilizes either a steel ball or a conical diamond known as a brale and indicates hardness by determining the depth of penetration of the indenter under a known load. This depth is relative to the position under a minor initial load; the.We offer Rockwell-Type Hardness Testers for every budget, including a full collection of accessories and hardness standards. . Ball bearing guided spindle mechanism; Built-in dial-a-weight system; Heavy-duty cast housing protects from dust and corrosion; Conforms to tolerances per ASTM & ISO 17025 Standards . Learn More Hardness Standards

The Rockwell Hardness Tester operates on the principle of measuring the depth of penetration of an indenter under a large load (major load) and a subsequent small load (minor load) into the surface of a material. . It typically consists of a mechanical or hydraulic mechanism that controls the application of the minor and major loads.Measure The Indentation: After removing the load, measure the remaining indentation depth using the depth-measuring mechanism of the Rockwell hardness tester. Read The Hardness Value: Refer to the Rockwell hardness test chart, which correlates the indentation depth with the corresponding hardness value for the specific test scale and indenter .The Rockwell hardness (HR) is then determined from the residual indentation depth, along with a few other factors (see below). In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to .

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.

The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. . if there is dirt or grease in the contact area between the anvil and the elevating screw or the elevating screw mechanism itself this will .

The 3831Digital Rockwell Hardness Tester can be used directly to measure the most popular regular Rockwell hardness scales and it can quickly convert that hardness value into HB, HV, HLD, HK and many other scales. Loaded with many useful features such as ultra precise results, wide measuring range, scale and test force selectable, automatic .The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic ScalesROCKWELL HARDNESS TESTER FR-X1, FR-X2, FR-X3 / FR-X1L, FR-X2L, FR-X3L Series. TOP; PRODUCT; . STABLE LOADING AXIS MECHANISM Adopted highly sensitive load shaft to prevent the side shift by the introduction of ball guide at the top and bottom. . (Load and release of the test load, and hardness indication are automatic) FUNCTION OF DATA .

Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications.Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs.

rockwell hardness test explained

this tester uses the standard test method for rockwell and Superficial rockwell hardness testing per AStM e-18. 2.1.1 Basic Operation 1. turn power switch on (back of the tester). the display will read SeLF teSt 2. After a few seconds the display will change to show the scale and status, for example: HrC Set 3.

The selection of test force is automatically adjusted once you select your hardness scale. There are three test forces of 60kgf(588.4N), 100kgf(980.7N) and 150kgf(1471N) for Rockwell hardness measurement, and also three test forces of 15kgf(147.1N), 30kgf(294.2N) and 45kgf(441.3N) for Rockwell superficial hardness measurement.

aggregate impact value test report pdf

rockwell hardness test diagram

11 de set. de 2023 · TESTEI MAIS UMA VEZ o Mystic Bingo Voyage! Mystic Bingo Voyage! Nesse video vamos falar sobre o aplicativo Mystic Bingo Voyage, onde que vou dizer se .

rockwell hardness tester mechanism|rockwell hardness calculation formula